Rennie Scaysbrook | May 4, 2020

Sometimes a motorcycle breaks the mold. Sometimes a motorcycle doesn’t just break it but annihilates it. Here’s a look at one such motorcycle.

If you need something inconspicuous to ride to the shops, the Vyrus Alyen is not it.

If you need something inconspicuous to ride to the shops, the Vyrus Alyen is not it.

To stand out in the world of custom motorcycle building, you need to create something truly outrageous. Italian company Vyrus has been breaking every mold they can find since 2003, creating ever more radical and extreme machines on a made-to-order basis.

We’ve sampled some Vyrus machines in the past, the most recent of which was the Vyrus 986 M2 Strada, the company’s failed Moto2 racer-turned-street bike. But the Alyen is something different entirely, a technical tour de force that looks unlike anything they (or anyone else for that matter) have created before.

The carbon-fiber body is a structured component of the chassis. The aesthetic is almost like a lizard!

The carbon-fiber body is a structured component of the chassis. The aesthetic is almost like a lizard!

Magnesium was used for the front and rear swingarm.

Magnesium was used for the front and rear swingarm.

“It’s a totally new concept,” says Vyrus’ CEO Ascanio Rodorigo. “Over the course of 10 years, 57 different versions were made between the designer Mr. Yutaka Igarashi and myself. “It’s a totally new placement of the parts in new volume and shapes.”

The Alyen utilizes the Vyrus trademark of a double swingarm/hub center steering system, whereby the front suspension, braking and steering forces are separated. This design helps maintain the correct steering geometry under braking, cornering and acceleration, although at the expense of some feel which riders have been conditioned to over the years through the employment of traditional telescopic forks.

Check out the graining of the uni-directional carbon-fiber handguards. Looks just like high-end woordgrain.

Check out the graining of the uni-directional carbon-fiber handguards. Looks just like high-end woordgrain.

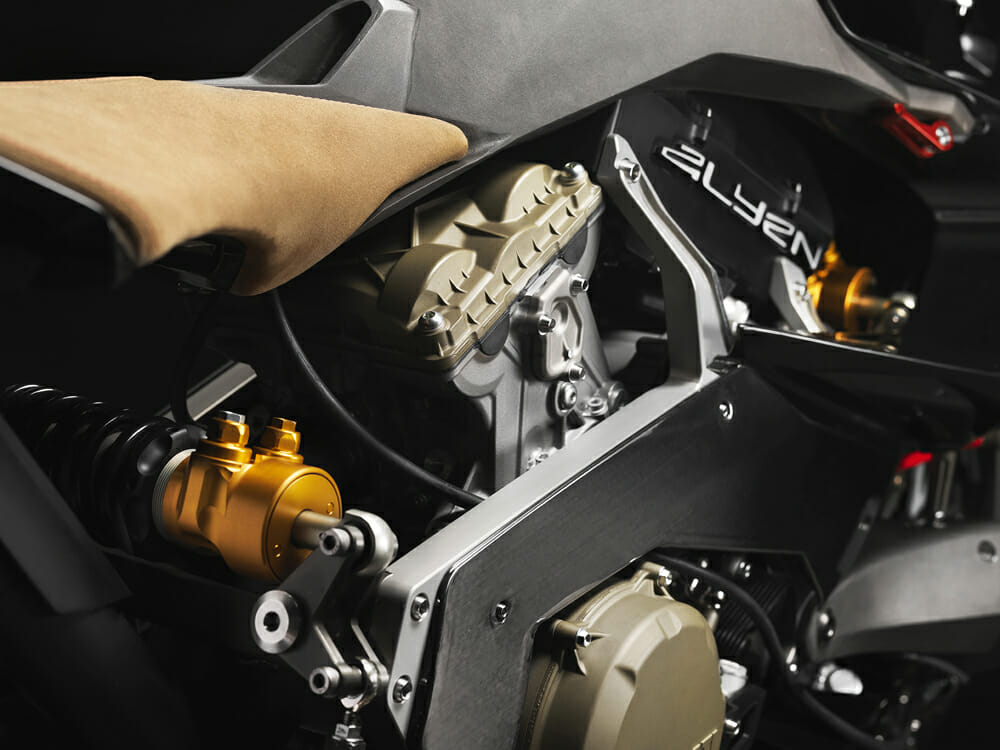

Notice the rear shock? It’s mounted perpendicular to the chassis.

Notice the rear shock? It’s mounted perpendicular to the chassis.

The steering system HWSS (Hydraulic Wired Steering System) is a mechanism developed by Vyrus that combines two steel cables tied to the ends of the handlebar and connected respectively to the sides of the wheel. The system is such that there are no connections at all between the handlebars and the front wheel, with the rider working in “remote control” as Vyrus puts it.

The motor has been donated by Ducati in the specially tuned Superquadro 1299 (1285cc), the last traditional Ducati V-twin superbike motor. Vyrus claims over 200 horsepower for the Alyen, yet this is probably the least interesting part of the motorcycle.

The front swingarm is a Vyrus trademark.

The front swingarm is a Vyrus trademark.

Slovenian company Rotobox created these stunning carbon-fiber wheels for the Alyen.

Slovenian company Rotobox created these stunning carbon-fiber wheels for the Alyen.

The motor is encased in a magnesium Omega chassis, which allows for the use of the flat front swingarm. The frame is essentially a C-shape, which frees up much needed space around the front of the motorcycle for the required steering parts. This chassis design was pioneered by Bimota with the first Tesi model, and later Yamaha with the GTS 1000.

Magnesium was also used when creating the front and rear swingarms, the footpegs, shift lever, anchoring beams and the suspension anti-dive. The rear suspension shock absorber is an Ӧhlins TTX40 unit and sits directly under the carbon-fiber seat unit, perpendicular to the swingarm, while Brembo supplies the brakes in either 320mm carbon ceramic discs/four-piston calipers, or racing spec 320mm T-drive discs.

The exhaust mufflers are more like trumpets. They will not be quiet, that you can guarantee.

The exhaust mufflers are more like trumpets. They will not be quiet, that you can guarantee.

Carbon fiber cloaks the Alyen in every direction, with the body a load-bearing structure and the various parts cooked in an autoclave at 120° C (250° F). Vyrus’s use of uni-directional (UD) fabric gives the finished product a wood-grain finish.

“The expertise needed to make UD structures—it’s superfine and not easy to make—this contributes to enhancing the product,” says Rodorigo. Carbon fiber also extends to the wheels, which are exclusive five-spoke items created by Slovenian company, Rotobox, and wrapped in Pirelli Supercorsa SP rubber.

The dash was made exclusively for the Vyrus from Australian company, Cobo.

The dash was made exclusively for the Vyrus from Australian company, Cobo.

As for the CNC machined controls, there are no exposed wires, with everything moved inside the hollow handlebar to give a minimalist look (probably the only time you could consider that term for the Vyrus). The lights are full LED, with a daytime running light incorporated.

A face only a mother could love? That’s up to you—we think the Alyen looks amazing!

A face only a mother could love? That’s up to you—we think the Alyen looks amazing!

There’s few bikes out there that can match the Alyen for sheer presence, but it’s unlikely you’ll ever see one on the road.

“Price is not available at the moment, but it’s very expensive,” says Rodorigo, coyly. “Almost all are sold, there’s just few frames still available, and the first bike will be delivered in September.” CN