Press Release | March 3, 2018

Tire Talk | How a Continental Motorcycle Tire is Made | Brought to you by Continental Tires

You may not have ever thought about how the tires of your car, truck or motorcycle are made. Tire manufacturing is very complex. A tire is not just a round piece of rubber that holds air. Conti Moto, located in Hanover Germany, has been optimizing and improving the manufacturing systems of motorcycle tires for decades. In this story, we want to give you an idea of how various parts of a tire are made and also, how they are assembled.

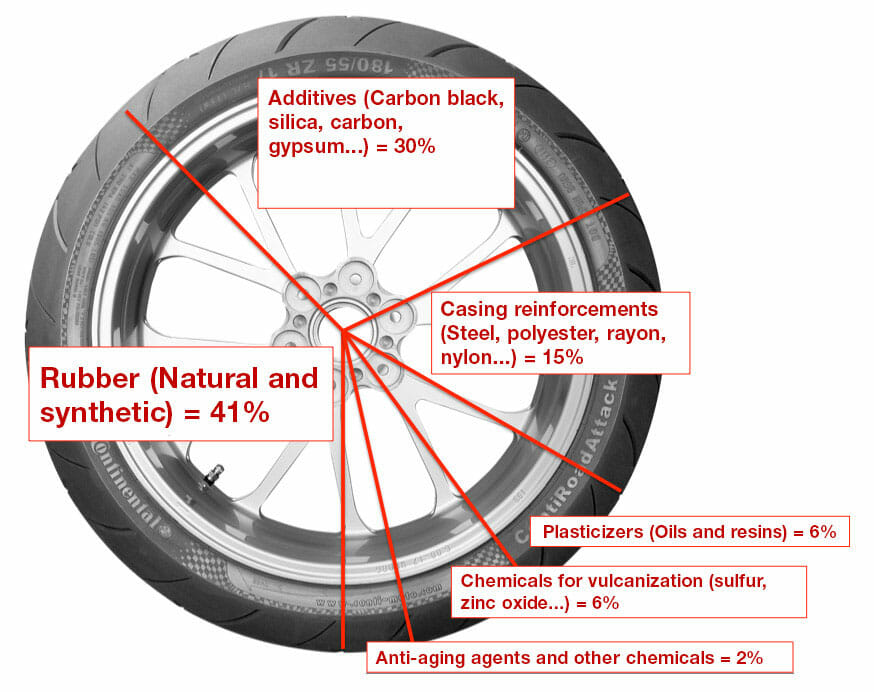

To begin, we will explain which materials are used to make a Continental tire.

A tire is mainly made of rubber (41%) with a mix of both natural and synthetic rubber. The natural rubber mainly comes from a tree called Havea Brasiliensis; however, other species are also used.

A tire is mainly made of rubber (41%) with a mix of both natural and synthetic rubber. The natural rubber mainly comes from a tree called Havea Brasiliensis; however, other species are also used.

These trees generate a resin that produces a milky solution called latex. Latex is one of the most expensive raw materials on earth because it’s a highly exploited natural resource. Continental, in collaboration with the Fraunhofer Institute of Molecular Biology and Applied Ecology in Germany, has made an important discovery; we’ve learned how to obtain the raw material latex from the roots of a dandelion. The synthetic rubber is made of a copolymerstyrene-butadiene. In that compound we add a series of additives (30%).

Some textiles and metals used in the carcass represent 15%. The remaining components represent 14%, which are what we call chemical additives that assist in the process of manufacturing or that they help to increase tire life.

The manufacturing of a tire is divided into a five-part process:

- Construction of the Tread

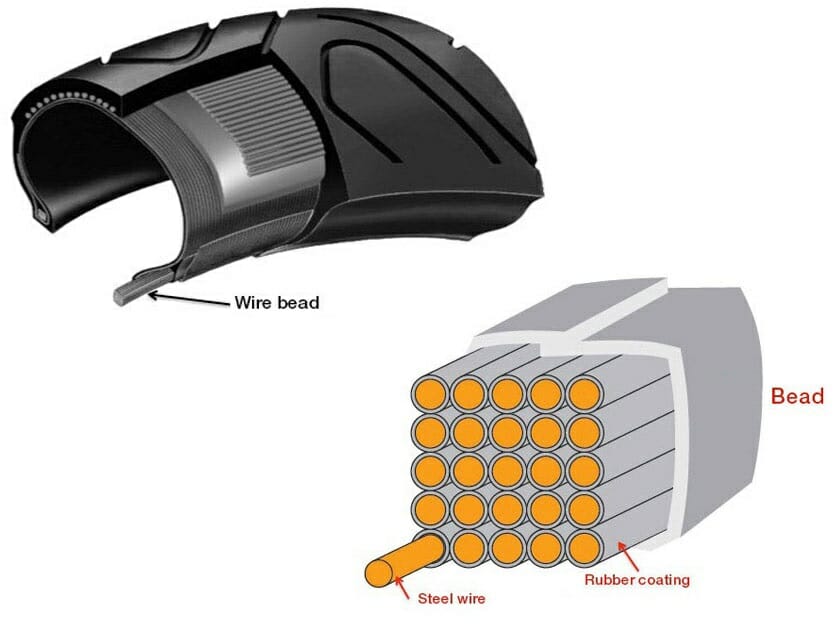

- Construction of the Bead (Steel wires covered heavily in rubber)

- Construction of the carcass layers

- Construction of the carcass belt

- Construction of the sidewall

The manufacturing process begins in a big machine called Banbury (below left), which is a big mixer. In this machine, sulfur, carbon, solvents, natural and synthetic rubber, are mixed.

This mixture goes through rollers (above right) that mix the components again and creates a thin sheet with the desired thickness.

The beads are made with steel wire covered in rubber. The beads are one of the most important parts of the tire because it creates the air-tight attachment to the rim.

The fabrication of the carcass layers is done with weaving machines, similar to the ones that make fabric to make the tread weave. Rayon, nylon, polyester and other materials are used. The layers are a textile fabric with the shape of a strip and covered with rubber. These strips are cut out to the tire size and the carcass is built.

The carcasses rest while we make the next component.

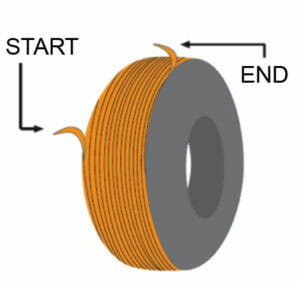

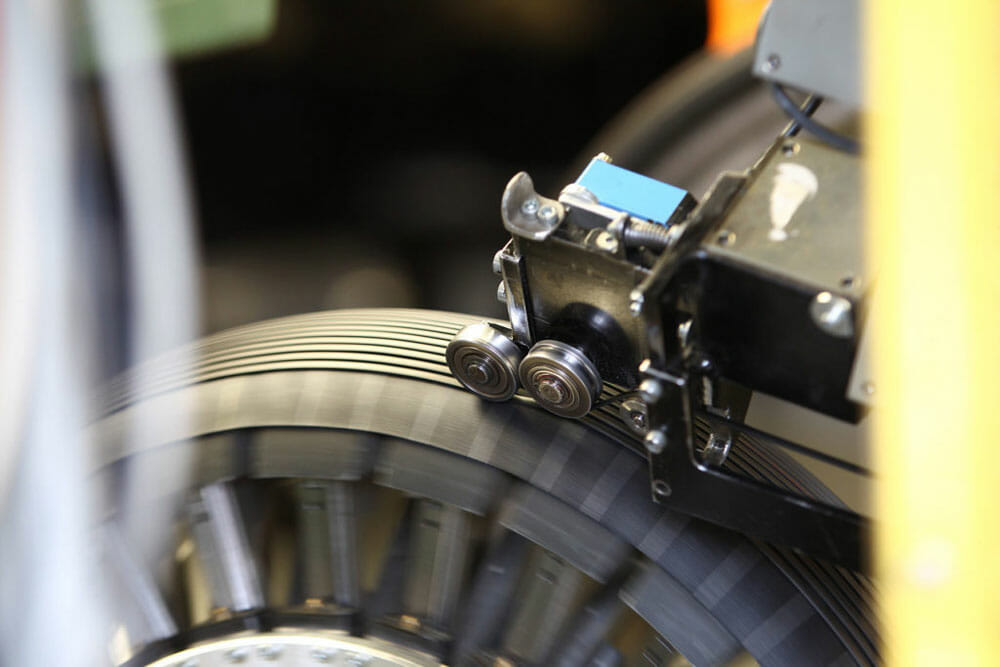

In the next picture, we can see our radial tires with our latest technology “Zero Degree Belt.” It’s a belt that has the shape of a spiral and wraps around the carcass. We start with the steel wires that will form this belt.

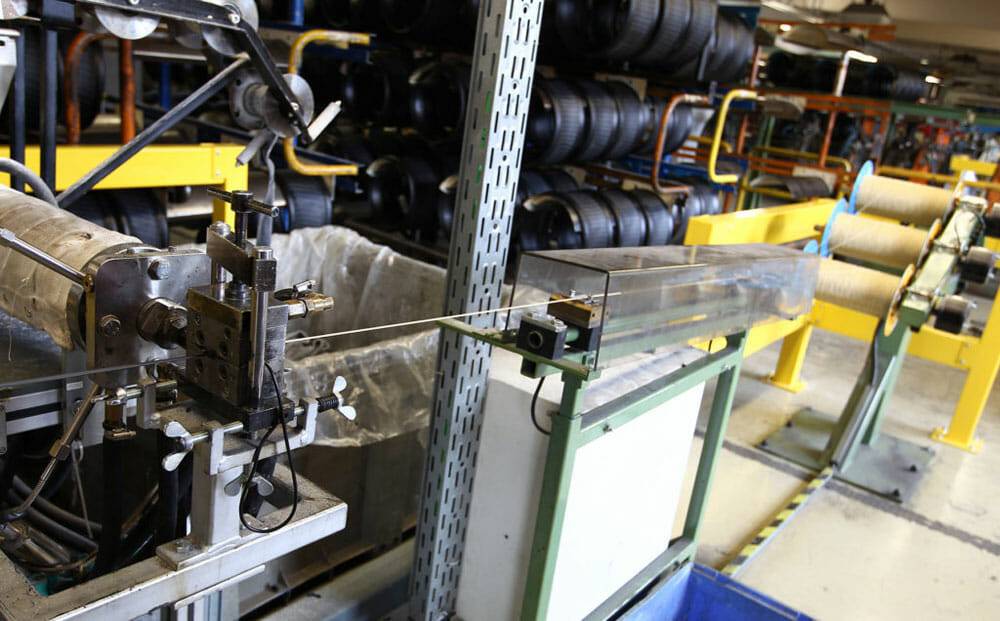

A machine (pictured below) pulls them tight, covers them with rubber, and then rolls it onto the carcass that we had previously built.

The carcass is placed into a matrix/mold that will give its shape and will prepare it to receive the “Zero Degree Belt.”

In this picture (below), we can see with detail how the belt is added to the carcass. The machine places the steel wire covered with rubber around the tire while synchronized rotations create a spiral.

And…finally, we have the carcass with the belt assembled! The next step will be to build the sidewalls of the tires. These are the parts that provide stiffness to the tire.

We assemble all the parts that make up a Continental tire: the carcass with the steel belt, the tread, the sidewall, the beads, and then, we will have a “green tire,” similar to a slick tire because it has no grooves.

This now looks like a real tire. Now all we have left is putting the tire into the mold/matrix with the right temperature and curing time. It will melt the tread pattern and will make all the grooves and sidewall labeling.

Finally, we will have the tire made, but it still won’t be ready to bring over to the warehouse.

The most important step is missing.

In the final process, once the tires are built and checked, some of them are randomly selected for speed and strength tests in machines with rollers.

Also, all the tires are visually inspected to detect any irregularity, defect, or deformity that would make the tire unacceptable for riding.

Before it goes to the warehouse, we will give them a final touch up, called “deburring,” to remove any excess rubber from the molding process.

Finally, we have a Continental motorcycle tire ready to be sent to motorcycle riders around the world.

For more information on Continental Tires, please visit: https://www.contimotousablog.com/