Michael Scott | March 15, 2017

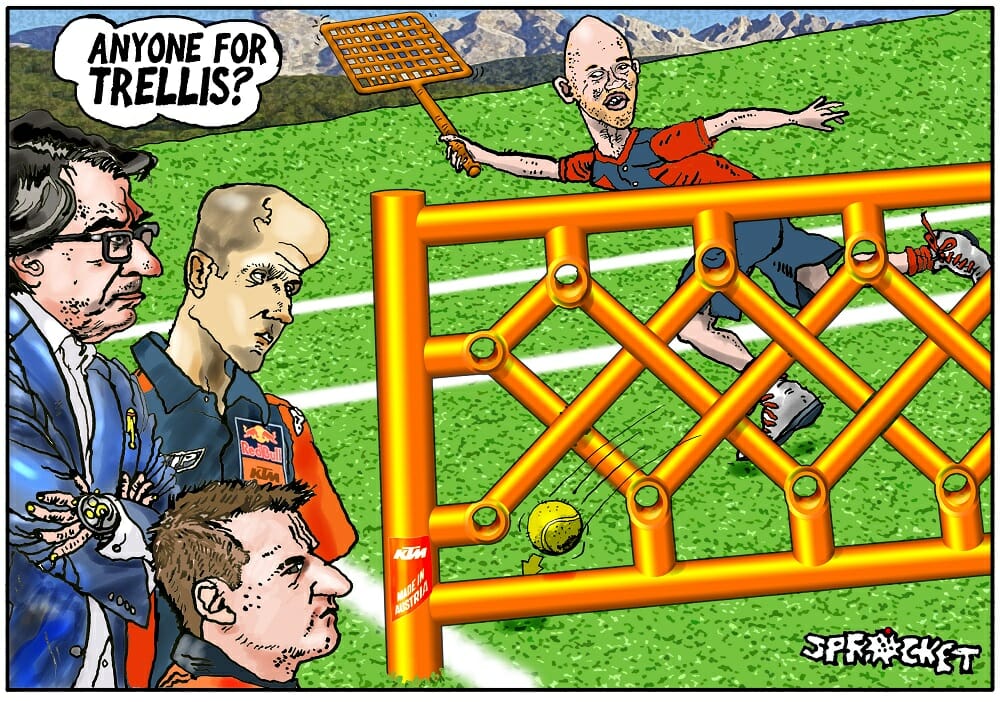

Anyone For Trellis?

There’s always a frisson when a new manufacturer dives headlong into the top level of racing. Will they make it? Or will the waters be too deep?

More of a frisson still when they eschew conventional racing practice to embrace novelty. After all, what succeeds in racing is what succeeded last year, plus a couple of percent. The same mantra upon which the Japanese bike industry achieved its strength: copy, but improve.

So when, for example, Aprilia greeted the new 990cc four-stroke era with a unique and sonorous in-line triple designed by racing-car firm Cosworth, it was not so great a surprise that it was ultimately found wanting. It was very fast as well as very noisy. But also very difficult to ride. Honda’s successful V5 was also unconventional, but based around familiar V4 motorcycle technology, and performed like a motorcycle.

Now it’s KTM’s turn. And while their V4 engine is in line with main rival Honda’s (although the vee angle and firing intervals remain a closely guarded secret) the Austrians have been unable to stop themselves from the same heresy that has marked their participation in the less demanding technical enclaves of the smaller classes.

They are using that old and long since out-dated chassis construction—welded steel tubes.

But is it really outdated?

If you look back at history, yes. And if you look at the history of heretical chassis designs, ditto. Just remember what happened to those off-the-wall French Elfs. Designed by a noted rally car engineer, they espoused among other things double-wishbone suspension and underslung chassis members in ways that made perfect sense in the laboratory. And never got anywhere until the very end, when they adopted bike-style semi-telescopic front forks instead.

Steel tubes were superseded in the 1980s, when extruded complex-section aluminum tubes came into fashion, with fabricated box-section aluminum a viable alternative.

There were several missed cues and false turnings—some of the early attempts simply tried to replicate steel-tube designs with square-tube aluminum—which was as bendy as a toothbrush under hot water. But it later transpired that the Holy Grail of the time was itself a false idol.

Everyone thought that a chassis should be completely stiff. Only in this way could the carefully considered chassis geometry be preserved under the stress of progress. This in turn would allow the suspension to work accurately, and everything to operate as the designers intended.

To this end, there had been some earlier experiments in carbon fiber, most notably by Suzuki’s by-then independent Britain-based near-factory team, battling to find ways to keep their obsolescent square-four RG500 engine competitive.

Racing car designer Nigel Leaper introduced a material then popular on four wheels (and still widely used in commercial aircraft) for its combination of light weight and tremendous stiffness, especially when correctly braced—synthetic honeycomb sandwich board. Not for nothing was the resulted glued-and-bonded chassis nicknamed “the cardboard box.” It was very stiff indeed. And ultimately turned out to be very hard to ride.

Over the next few years, metal chassis which on paper failed the ultimate stiffness test actually turned out to be more effective on the track. It was a matter of “feel,” something riders talk about a great deal.

The truth filtered into general consciousness: extreme stiffness may be correct for a car, but it is wrong for a motorcycle. What a single-track vehicle needs, especially with the ever more acute angles of lean achieved on fast-improving tires, was to be able to flex. But only in the right way. Which is in itself a complicated matter.

Controlled flex has been the new Holy Grail for well over 10 years, and remains so. Experiments continue in tailoring stiffness so that the chassis resists the massive stresses of hard braking, but yields to bumps when at high angles of lean, when the suspension itself cannot absorb them.

And greater understanding of the design of aluminum spars continues to pay dividends in taming chatter and increasing corner speeds.

But there’s no technical reason why steel cannot be engineered to give similar results. At least, that is what KTM thinks. And, funnily enough, what Ducati thought, when they entered MotoGP with a steel trellis frame in 2003. I’ve never forgotten the elegant response from Claudio Domenicali, then head of Ducati Corse and now CEO, when I asked him if he thought a steel trellis was the right idea.

“That,” he replied, “is like asking your host if the wine is good.”

Well, it was fairly good, but by the time genius rider Casey Stoner won the title in 2007, the steel tubes were merely a vestige, and Ducati had embarked on an affair with super-stiff carbon fiber that almost cost Rossi his career, and from which they are only now recovering.

We wait to see how good Austria’s wine will be.CN

Click here to read more MotoGP News.